Design, Fabrication, and Construction Automation

The successes of digital practice have been significantly driven by automating traditional design, engineering, and construction processes. These automated processes are a key component of integrated digital practice and a key efficiency of building information modeling. These capabilities reduce the cost of manual work, decrease cycle time, allow more iteration, and enable optimization of the end product.

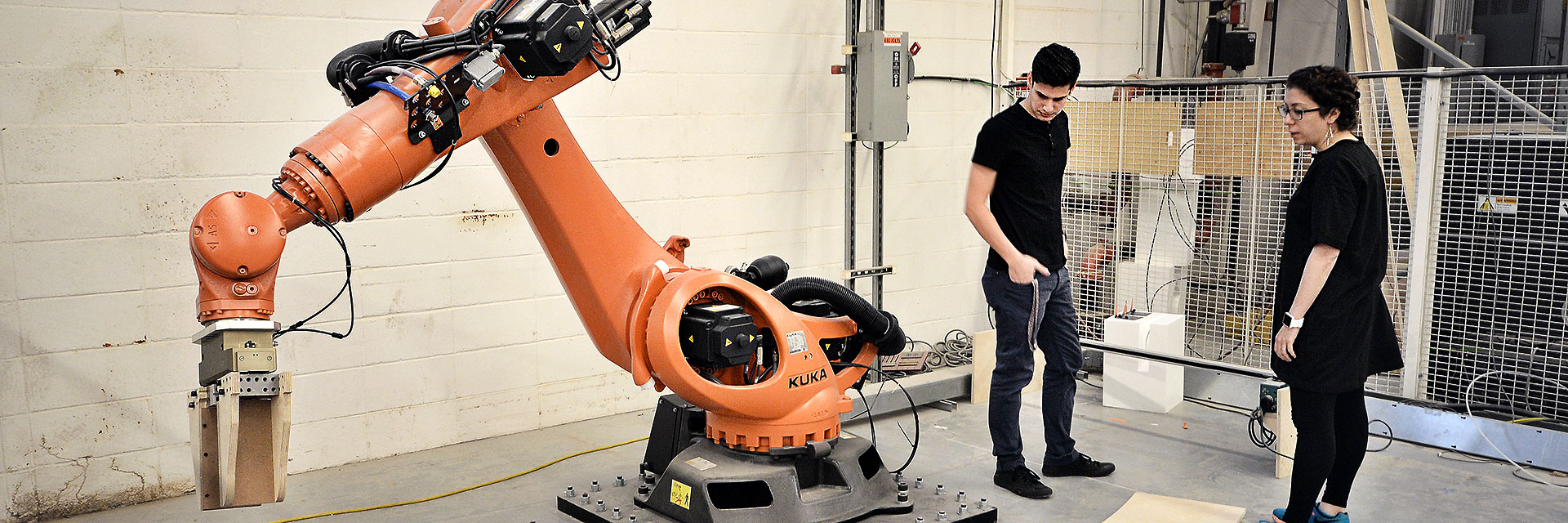

The DBL brings a number of distinct capabilities that create a unique environment for advancing automated design and construction practices. The lab’s partner program connects technology partners with professional members who have specific aspects of practice they seek to advance.

The lab’s focus on advanced computing research -- from geometry and parametric modeling to machine learning and data analytics -- brings a spectrum of the industry's leading expertise and resources to develop and implement strategies for automating the design and engineering of specific projects and systems. Automated design methods in turn support follow-on capabilities, including design optimization and data analysis. These capabilities in design and engineering automation are matched by its capacities in fabrication and construction automation.